Black Bear Mountain Stone

Hackett Stone - Rustic

Hackett Stone - Rustic

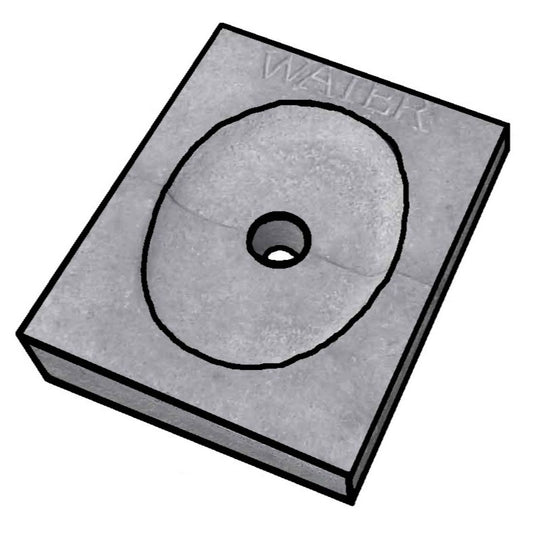

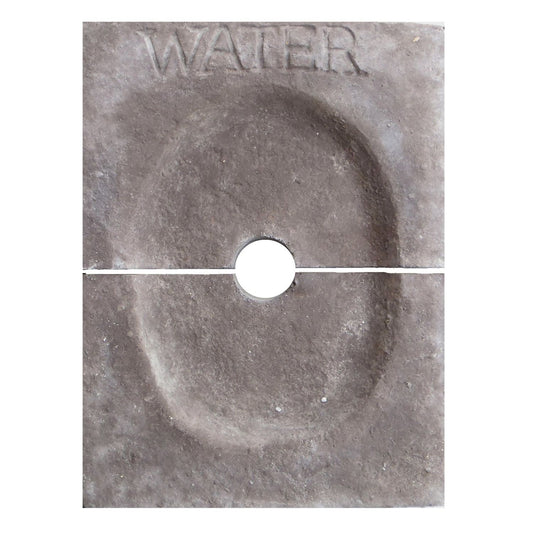

Couldn't load pickup availability

Black Bear Mountain Stone hackett stone rustic truly captures the old-world style with the appearance of majestic European castles of old. A variety of depths and sizes help this pattern to create an architectural elegance. The ease of installation makes this manufactured stone veneer a favorite of masons as well as do-it-yourselfers. Also known as castle rock or castle stone. Hackett stone is a stone veneer product measuring 1" to 1.5" thick and therefore thinner than traditional stone siding for easier, lighter handling. All our manufactured stone veneer products are suitable for interior applications such as stone accent walls or stone fireplaces as well as exterior applications such as stone veneer siding. Black Bear Mountain Stone hackett stone is available in boxes of 10 square foot flats, boxes of 6 lineal foot matching corners, and 150 square foot bulk crates.

- American made: high quality stone veneer, made in the USA.

- Premium manufacturing: to ensure you get the best stone veneer, Black Bear Mountain Stone strictly monitors every step of the production process for quality control.

- Color Lock technology: the stone face color has bonding agents in it to help protect against fading from harsh environmental conditions, cleaners, and even pressure washing (see installation and maintenance documents for more information).

- Application options: suitable for interior and exterior installations, and residential or commercial applications.

- Try before you buy: samples are available on all of our stone veneer products.

- Strong hold grip: grooves are raked onto the back of every stone ensuring a durable, lasting installation.

- Engineered to endure: stone veneer manufactured to last, we back it up with our 50 year limited manufacturer's warranty.

- Commercially rated: no job is too big or too small, our stone veneer is great for any and all commercial and business properties.

- Reviews from real customers: don't take our word for it, see what our customers have to say about Black Bear Mountain Stone.

- Free Shipping: all Black Bear Mountain Stone orders ship for free in the continental USA.

- Individual Stones

- Made to Order

- Free Shipping

Order Samples

Order Samples

Samples are available on all of our hackett stone products.

Dimensions

Dimensions

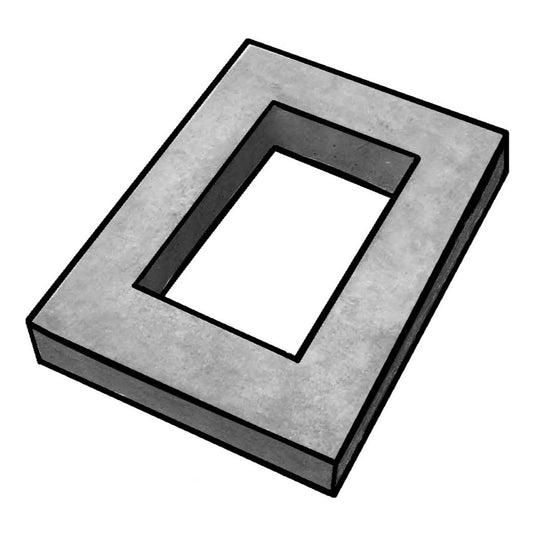

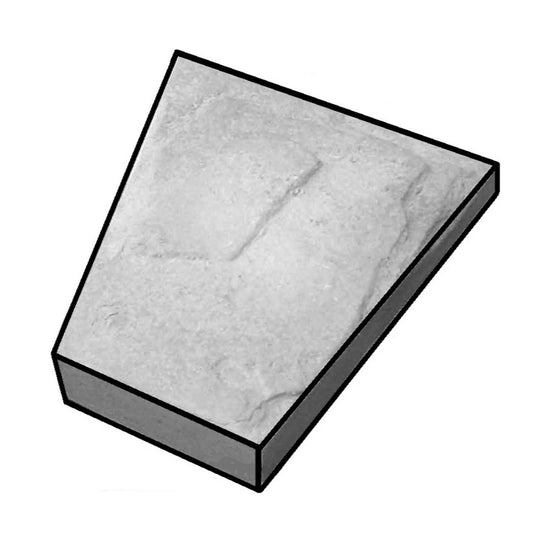

Stone flat dimensions:

Length: 4.5" to 15.5"

Height: 2" to 9.5"

Thickness: 1" to 1.5"

Corner dimensions:

Short side: 3" to 4"

Long side: 10" to 12"

Height: varies to match stone style

Each 10 square foot box weighs roughly 80-90lbs and corners weigh roughly 70-80lbs per box. Each 150 square foot bulk crate weighs roughly 1450lbs.

Materials

Materials

Black Bear Mountain Stone hackett stone is produced by combining Portland cement, lightweight aggregate, and iron oxide mineral colors.

Minimum Order Details

Minimum Order Details

All products have a minimum order quantity. Orders for less than the minimum order quantity will be cancelled. Hackett stone has a minimum order quantity of 100 square feet.

Corners are add on items and cannot be sold and shipped independently of stone veneer flats. Orders for corners independent of stone veneer flats will be cancelled.

Accessories are add on items and cannot be sold and shipped independently of stone veneer flats. Orders for accessories independent of stone veneer flats will be cancelled.

Please see our shipping policy and our terms of service for more information.

Overage

Overage

We recommend ordering an additional 10–15% to account for waste from cuts, fitting adjustments, or potential breakage during installation and shipping.

Order Processing Time

Order Processing Time

Please note: All of our stone veneer is made to order. Manufacturing time is currently 4-6 weeks. You will receive an email with an estimated ready to ship date after your order has been placed.

Shipping & Returns

Shipping & Returns

For more information on shipping and returns please see our full shipping policy and our full refund policy. Have a question about shipping or refunds? Contact us

Care & Maintenace

Care & Maintenace

For more information on care & maintenance, please see our full care & maintenance guide. Have a question about care & maintenance? Contact us

Installation Instructions

Installation Instructions

Hackett stone is an individual stone product and is installed piece by piece. The individual stones will vary in size, shape, and thickness. In order to achieve the desired natural stone finish as shown in our images it is up to the installer to arrange the individual stones in the correct pattern and install each stone one at a time. For more information on installation, please see our full installation instructions. Have a question about installation? Contact us

Warranty Information

Warranty Information

For more information on our 50 year limited manufacturer's warranty, please see our warranty guide. Have a question about our warranty? Contact us

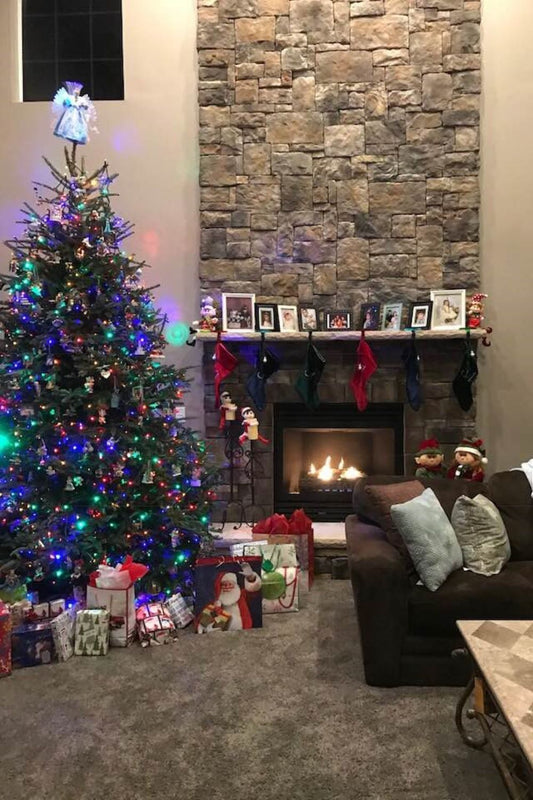

About Our Images

About Our Images

We do not use image creation services, AI-generated images, or computer-generated imagery (CGI) to showcase our stone veneer products. What you’re seeing is real work done by real people, homeowners, contractors, designers, and business owners who chose our stone veneer and took the time to share their finished results with us. There may be some differences from image to image, however this variation is caused by different lighting conditions and image quality. Additionally, images can look different from screen to screen.

Unfortunately, if there are no other images on our website, that is because we have not received any images from our customers yet.

Contact Us

Contact Us

Have a question ? Contact us

Share

Thank you, Carl. Youve been very patient and accommodating, we appreciate it!

5 stars

Thank you for everything.

We absolutely love our stone! It turned out beautiful! We could not find stone in our area that we like and could get in a reasonably amount of time. Somehow I stumbled upon Black Bear Mountain Stone. From the initial contact all the way through getting our stone delivered Carl was great! They are a small family owned business which I love, Carl was very easy to get in contact with, he is very accommodating and we were able to get our stone in a very timely manner. I felt very comfortable ordering from him. Plus they are a Christian family which was a blessing for us!

We are happy with the sample. We have not done the budget to know if we will buy the full product, but of the 3 product types we have looked into for exterior siding and trim, this is the preferred choice.

More Hackett Stone

-

Hackett Stone - Midnight

5 reviewsRegular price From $69.54 USDRegular priceUnit price / per -

Hackett Stone - Rustic

10 reviewsRegular price From $69.54 USDRegular priceUnit price / per -

Hackett Stone - Buck Mountain

7 reviewsRegular price From $69.54 USDRegular priceUnit price / per -

Hackett Stone - Aspen

4 reviewsRegular price From $69.54 USDRegular priceUnit price / per -

Hackett Stone - Kona

4 reviewsRegular price From $69.54 USDRegular priceUnit price / per -

Hackett Stone - Ozark

3 reviewsRegular price From $69.54 USDRegular priceUnit price / per

Don't Forget Accessories

Questions & Answers

Have a Question?

-

Need more installation info, looking to use as a backsplash. Cost per square foot?

Thank you for your question and interest in our stone veneer. Our stone veneer is suitable for interior and exterior installations, including backsplashes. We recommend our stone veneer and brick veneer are sealed when used in a backsplash. A concrete sealer is not required, however, sealing with a concrete sealer will add protection especially over the mortar joints. Please keep in mind that different concrete sealers will affect the appearance of the stone veneer. A matte (or flat) finish will have little to know impact to the finished look of the stone veneer whereas a gloss finish will darken the stone veneer and have a wet look. We recommend testing your concrete sealer on a piece of stone veneer that has not been installed to ensure you are happy with the finished appearance after applying concrete sealer. Our installation instructions can be downloaded at https://blackbearmountainstone.com/pages/post-purchase-support. For the surface prep, which is the most important step, you will need to install a moisture barrier and then install wire lath over that. Make sure the nails or screws for wire lath hit studs to ensure a good foundation. Your scratch coat goes over the wire lath and then the stone veneer. We recommend our stone veneer and brick veneer be installed with Type S mortar. Mortar is recommended for installation opposed to an adhesive as mortar is cheaper than adhesive, and when installing with an adhesive you must hold the stone in place until the adhesive sets which really slows down installation time, whereas mortar instantly holds. Our pricing is available on our website. As our pricing can change it is best to view the price on each product page prior to placing your order. Please let us know if you have any more questions!

-

Hi, I was wondering how the bulk orders come? Do they come on sheets to make install easier?

Thank you for your question and interest in our stone veneer. The delivery truck will have a liftgate and pallet jack to unload your order, no loading dock required, but it is a lot easier to unload and move around with a forklift if available on site. Our hackett stone profile is not a panel system, they are individual stones. There are 10 square feet of flats per box and 6 lineal feet of corners per box. The individual stones will vary in size, shape, and thickness. To achieve the desired natural stone finish as shown in our images it is up to the installer to arrange the individual stones in the correct pattern and install each stone one at a time. If you are looking for a panel system, our ready stack profile is a mini panel stone product and is installed in sections at a time https://blackbearmountainstone.com/collections/ready-stack. Each panel measures 4” high but will vary in length (5.5”, 8.25”, 11”, 16.5”) and thickness (1.5”-2.5”). Each ready stack panel has multiple stones on each panel face. To achieve the desired finish as shown in our images it is up to the installer to arrange the panels in the correct pattern and install each panel one at a time. Please let us know if you have any more questions!

Popular Samples

-

Stack Stone - Black Forest SAMPLE

No reviewsRegular price $20.00 USDRegular priceUnit price / per -

Stack Stone - Midnight SAMPLE

No reviewsRegular price $20.00 USDRegular priceUnit price / per -

Ledge Stone - Rustic SAMPLE

No reviewsRegular price $20.00 USDRegular priceUnit price / per -

Stack Stone - Ozark SAMPLE

No reviewsRegular price $20.00 USDRegular priceUnit price / per -

Field Stone - Mossy Creek SAMPLE

No reviewsRegular price $20.00 USDRegular priceUnit price / per -

Field Stone - Rustic SAMPLE

No reviewsRegular price $20.00 USDRegular priceUnit price / per -

Lime Stone - Tuscany SAMPLE

No reviewsRegular price $20.00 USDRegular priceUnit price / per -

Lime Stone - Adaline SAMPLE

No reviewsRegular price $20.00 USDRegular priceUnit price / per -

Ledge Stone - Mossy Creek SAMPLE

No reviewsRegular price $20.00 USDRegular priceUnit price / per -

Ledge Stone - Midnight SAMPLE

No reviewsRegular price $20.00 USDRegular priceUnit price / per -

Field Stone - Midnight SAMPLE

No reviewsRegular price $20.00 USDRegular priceUnit price / per -

Ledge Stone - Kona SAMPLE

No reviewsRegular price $20.00 USDRegular priceUnit price / per

Our Best Sellers

-

Stack Stone - Black Forest

33 reviewsRegular price From $86.93 USDRegular priceUnit price / per -

Field Stone - Mossy Creek

28 reviewsRegular price From $69.54 USDRegular priceUnit price / per -

Ledge Stone - Rustic

59 reviewsRegular price From $86.93 USDRegular priceUnit price / per -

Stack Stone - Midnight

26 reviewsRegular price From $86.93 USDRegular priceUnit price / per -

Stack Stone - Ozark

53 reviewsRegular price From $86.93 USDRegular priceUnit price / per -

Ledge Stone - Aspen

58 reviewsRegular price From $86.93 USDRegular priceUnit price / per -

Field Stone - Rustic

40 reviewsRegular price From $69.54 USDRegular priceUnit price / per -

Lime Stone - Tuscany

41 reviewsRegular price From $69.54 USDRegular priceUnit price / per -

Stack Stone - Rustic

14 reviewsRegular price From $86.93 USDRegular priceUnit price / per -

Ready Stack - Alabama

19 reviewsRegular price From $75.34 USDRegular priceUnit price / per -

Field Stone - Aspen

10 reviewsRegular price From $69.54 USDRegular priceUnit price / per -

Ledge Stone - Mossy Creek

47 reviewsRegular price From $86.93 USDRegular priceUnit price / per -

Ledge Stone - Amber

16 reviewsRegular price From $86.93 USDRegular priceUnit price / per -

Ready Stack - Black Forest

20 reviewsRegular price From $75.34 USDRegular priceUnit price / per -

Field Stone - Kona

10 reviewsRegular price From $69.54 USDRegular priceUnit price / per -

Ready Stack - Cool Gray

12 reviewsRegular price From $75.34 USDRegular priceUnit price / per -

Lime Stone - Rustic

12 reviewsRegular price From $69.54 USDRegular priceUnit price / per -

Field Stone - Midnight

21 reviewsRegular price From $69.54 USDRegular priceUnit price / per

Recent Blog Posts

-

Does Manufactured Stone Need Sealing?

Manufactured stone veneer (MSV) is a popular choice for adding the beauty of stone to both interior and exterior spaces without the hefty cost or weight of real stone. It’s...

Does Manufactured Stone Need Sealing?

Manufactured stone veneer (MSV) is a popular choice for adding the beauty of stone to both interior and exterior spaces without the hefty cost or weight of real stone. It’s...

-

Can Stone Veneer be Used Inside?

Manufactured stone veneer, also known as faux stone or cultured stone, has become a go-to choice for homeowners and designers looking to bring the timeless beauty of natural stone into...

Can Stone Veneer be Used Inside?

Manufactured stone veneer, also known as faux stone or cultured stone, has become a go-to choice for homeowners and designers looking to bring the timeless beauty of natural stone into...

-

What is the Life Expectancy of Stone Veneer?

Manufactured stone veneer, also known as faux stone, has become a popular choice for homeowners and builders alike due to its aesthetic appeal, affordability, and versatility. It mimics the look...

What is the Life Expectancy of Stone Veneer?

Manufactured stone veneer, also known as faux stone, has become a popular choice for homeowners and builders alike due to its aesthetic appeal, affordability, and versatility. It mimics the look...

-

Stone Veneer Care and Maintenance

Manufactured stone veneer is a popular choice for homeowners and builders alike. Known for its aesthetic appeal, affordability, and versatility, it’s often used for exterior façades, fireplaces, feature walls, and...

Stone Veneer Care and Maintenance

Manufactured stone veneer is a popular choice for homeowners and builders alike. Known for its aesthetic appeal, affordability, and versatility, it’s often used for exterior façades, fireplaces, feature walls, and...